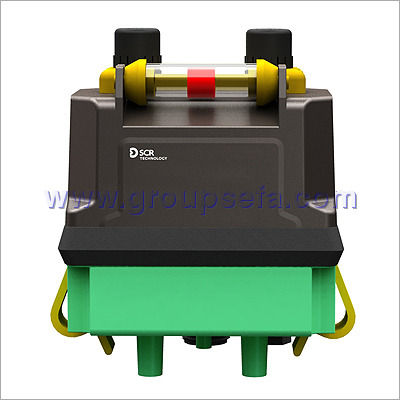

Data Flow System

Price 1000 INR/ Piece

Data Flow System Specification

- Product Type

- Data Flow System

- General Use

- Industrial Data Management

- Material

- Mild Steel

- Type

- Modular System

- Capacity

- Customizable as per requirement

- Weight (kg)

- Approx. 45-60 kg

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC (Programmable Logic Controller)

- Processing Pressure

- Standard Atmospheric Pressure

- Cleaning System

- Automatic Cleaning

- Cooling Mode

- Air Cooled

- Sterilization Method

- UV Sterilization

- Motor Power

- 0.5-2 HP

- Voltage

- 220-240 V

- Dimension (L*W*H)

- 1200 x 800 x 1800 mm

- Feature

- Robust Construction, High Efficiency, Long Service Life

- Color

- Silver Grey

- Network Protocols

- TCP/IP, Modbus, OPC

- Storage Capacity

- Integrated, scalable via SD/SSD

- Input Interface

- Multiple Digital & Analog Inputs Supported

- Mounting Type

- Floor / Panel Mounted

- Installation

- Easy plug-and-play setup

- Alarm System

- Audio-visual / SMS Alert

- Power Consumption

- 35-100 W

- Operating Temperature Range

- 0°C to 50°C

- Output Interface

- Ethernet, RS232/RS485, USB

- Display Type

- Touch Screen HMI

Data Flow System Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 3 Days

About Data Flow System

Key Features

- Reliable way to get information about cows' health and accumulated quantity of milk.

- PC-based system with 24/7 access.

- Contains management tools.

- Provides analytic report of individual cow.

- Improves decision making ability.

- PC-operated.

Customizable Modular Design

This Data Flow System features a truly modular architecture, allowing customization of capacity and input/output interfaces to match precise industrial requirements. Its scalable storage options, with support for SD and SSD expansion, ensure adaptability as data needs evolve. Constructed from durable mild steel and designed for either floor or panel installation, the system offers both flexibility and longevity in demanding operational settings.

Advanced Control and Connectivity

Equipped with a PLC controller and computerized automation, the system supports seamless industrial integration. Multiple digital and analog inputs are complemented by diverse output interfaces, including Ethernet, RS232/RS485, and USB. It accommodates major network protocols like TCP/IP, Modbus, and OPC, making data transmission efficient and reliable across different devices and platforms.

User-Friendly Operation and Maintenance

The integrated touch screen HMI streamlines user interaction, enabling real-time data visualization and intuitive control. Maintenance is simplified through an automatic cleaning function and robust, air-cooled design. UV sterilization further ensures optimal hygiene standards, while the easy plug-and-play setup enables swift commissioning and reduced installation time.

FAQs of Data Flow System:

Q: How does the Data Flow System support integration with existing industrial setups?

A: The system offers multiple digital and analog input interfaces, and supports widely used network protocols such as TCP/IP, Modbus, and OPC. Its diverse output options (Ethernet, RS232/RS485, USB) ensure compatibility with most industrial equipment, enabling seamless integration into existing infrastructures.Q: What are the primary benefits of using the touch screen HMI display?

A: The touch screen HMI display provides an intuitive and interactive interface for real-time data monitoring and control. It simplifies operational workflows, reduces training requirements for operators, and enhances overall system efficiency with visual prompts and controls.Q: When is the alarm system activated and what notification methods are available?

A: The systems alarm is triggered upon detection of predefined abnormal conditions, like equipment malfunctions or out-of-range measurements. It provides both audio-visual signals and SMS alerts, ensuring prompt notification for quick response and minimal downtime.Q: Where can this Data Flow System be installed and what are the mounting options?

A: The systems rugged mild steel build allows for both floor and panel mounting. Its plug-and-play design supports easy installation in a wide range of industrial locations, from control rooms to shop floors, depending on operational requirements.Q: What process does the system use for maintaining cleanliness and hygiene?

A: It features an automatic cleaning system and employs UV sterilization to maintain optimal hygiene levels. This reduces the need for manual intervention, minimizes contamination risks, and ensures consistent operation even in environments with stringent cleanliness demands.Q: How is the storage capacity managed and can it be expanded as data requirements grow?

A: The Data Flow System comes with integrated storage that is easily scalable via SD or SSD expansion. This flexibility allows users to adjust storage capacity as their data logging and management needs increase over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dairy Farm Equipment Category

Impulse Air

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Impulse Air Machine

Automatic : Yes

Feature : Other, Portable, Low noise, Energy Efficient

Color : Silver

Pulsatotr P201 Machine

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Pulsator Machine

Automatic : Other, SemiAutomatic

Feature : Other, Sturdy Design, Consistent Pulsation, Low Maintenance

Color : White & Black

Sefa TMR Machine

Price 600000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : TMR (Total Mixed Ration) Feed Mixer Machine

Automatic : Other, SemiAutomatic

Feature : Other, Robust Construction, Efficient Mixing, Low Maintenance

Color : Green

Milking Parlour

Price 600000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Milking Parlour

Automatic : Yes

Feature : Good Quality

Color : Silver

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS